Chlorinated Polyethylene Resin

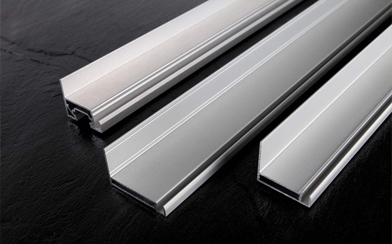

As an excellent impact modifier, Keliren® chlorinated polyethylene thermoplastic resin is widely used in PVC extrusion and injection molding products, including profiles, pipes, sheets and fittings. The addition of a small amount of Keliren® resin can greatly enhance the impact resistance of rigid PVC and improve its processing fluidity. In addition, due to its good chemical resistance, outstanding low-temperature performance, high filling capacity, excellent weather resistance and remarkable compatibility, Keliren® resin is used in a wider range of formulation systems.